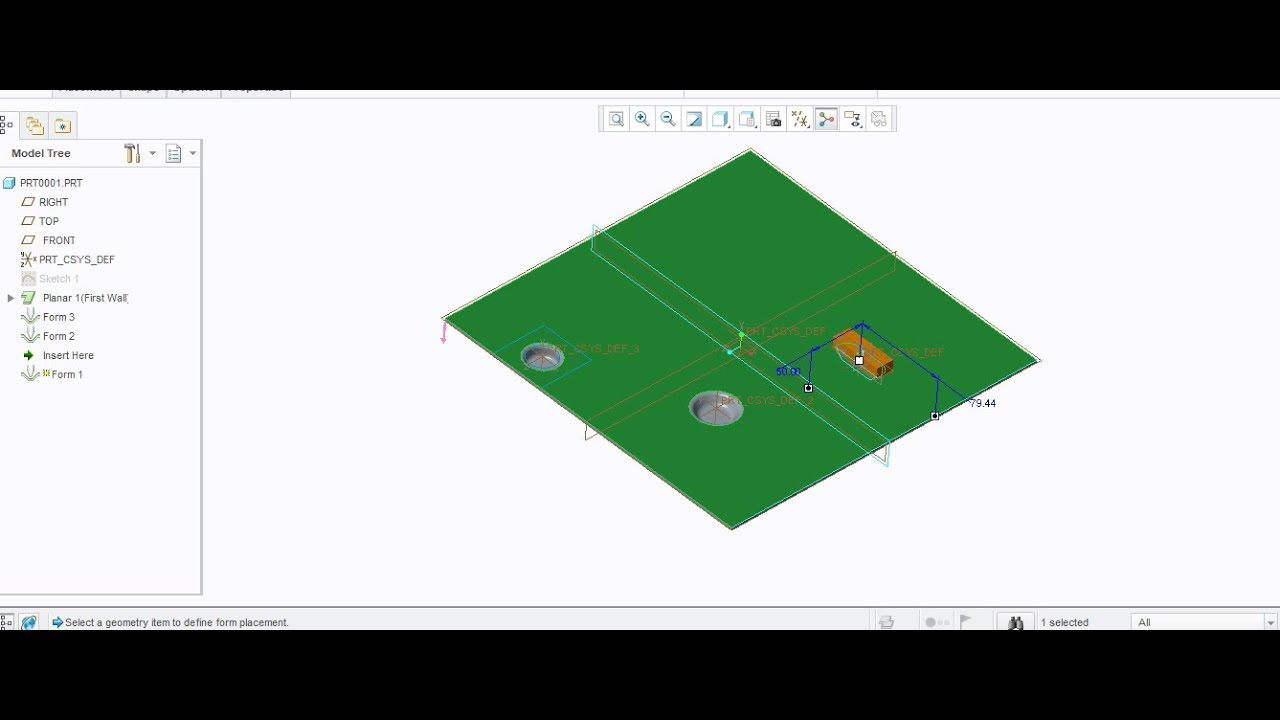

If the reference model has a coordinate system component interface configured you can quickly place a die form reference part as an on surface coordinate system or by using component interfaces.

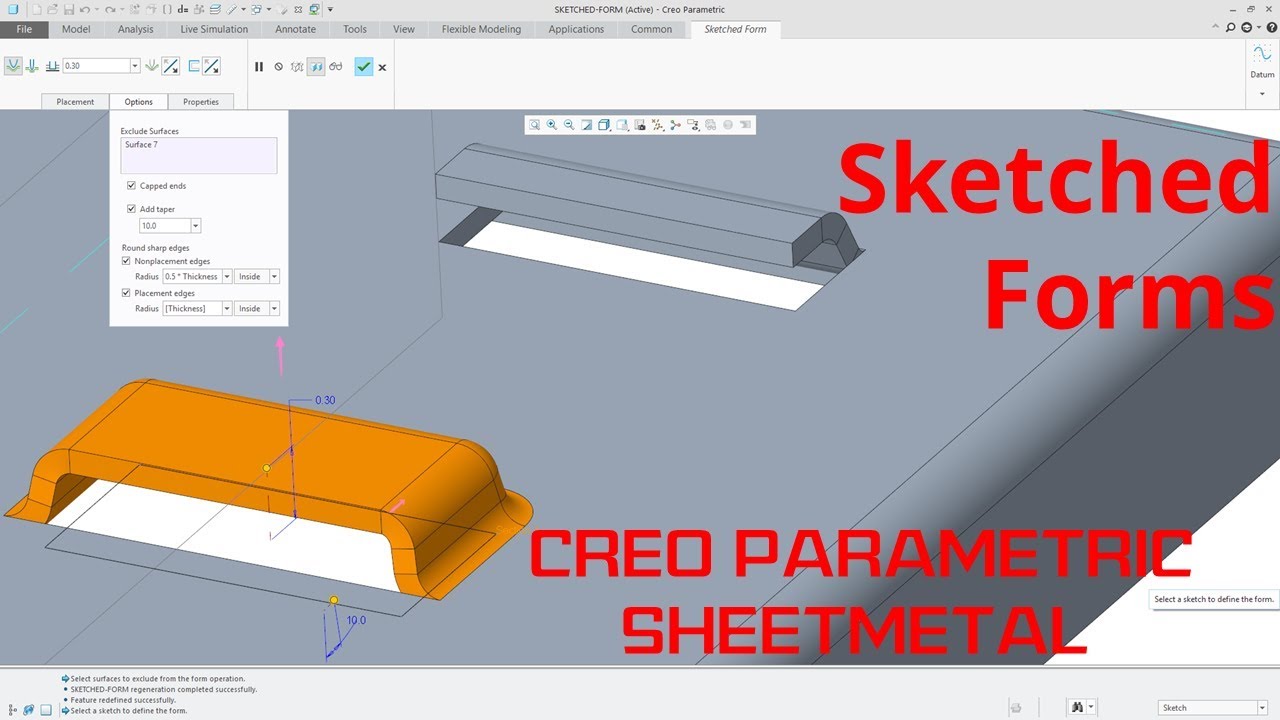

Creo sheet metal punch form.

How sheet metal forming components are designed in proe.

Creo sheet metal training.

Details opens the surface sets dialog box to add or remove surfaces from the punching process.

The die form workflows and user interface have been enhanced and modernized in ptc creo 3 0 so they are consistent with those of the punch form tool.

Exclude surfaces collects sets of surfaces excluded in the punching by the quilt form punch tool.

For more information on surface sets search the help center.

Using a variety of y and k factor bend allowance calculations designers can create flat patterns of the designs.

The point to be noted here is that you can use either a sheet metal punch or a die but not both to create a sheet metal forming feature in pro engineer.

How to create sheet metal punch and die in creo.

Hello friends if you guys planing to buy anything from amazon please send me the product details to my mail.

This comprehensive suite of creo sheet metal design tools helps users create features such as walls bends punches notches forms and relief features.

If you see the pic i attached there is a surface tear it shouldn t happen.